In the rapidly evolving world of robotics, servo controllers emerge as the unsung heroes, intricately governing the precision and efficiency of robotic systems. These compact yet powerful devices stand at the heart of modern robotics, enabling a vast array of machines to perform with remarkable accuracy and agility. From the delicate tasks of medical robots to the robust demands of industrial automation, servo controllers play a pivotal role in enhancing the capabilities and reliability of robotic systems. This comprehensive article delves into the essence of servo controllers, unraveling how they refine the operational excellence of robotics.

What are Servo Controllers in Robotic Systems

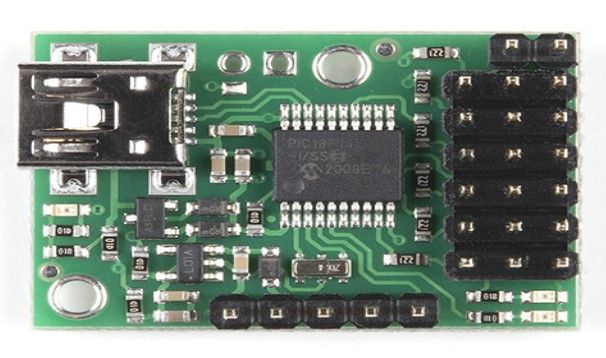

At the core of robotic innovation, servo controllers represent a critical technology that bridges the gap between mechanical action and digital instructions. Essentially, these devices regulate the movement of a motor to achieve desired positions, speeds, and torques with exceptional precision. Their significance in robotics cannot be overstated, as they enable machines to interpret and execute complex commands with finesse.

- Basics of Servo Control Technology: Fundamental to robotics, servo control systems comprise motors, potentiometers, and a control circuit.

- Importance in Robotics: These systems are indispensable for tasks requiring high precision, speed control, and adaptability.

How Do Servo Controllers Work?

Understanding the inner workings of servo controllers unveils the sophistication behind their seemingly simple operations. At their heart, these devices employ a feedback mechanism that continuously adjusts the motor's position based on the comparison between the desired and the actual position.

- Main Components:

- Motor: The actuator that drives the robot's movement.

- Potentiometer: Measures the current position of the motor shaft.

- Control Circuit: Processes input signals and controls the motor to reach the desired position.

Why Are Servo Controllers Essential for Robotic Systems?

The integration of servo controllers into robotic systems brings a multitude of benefits, making them indispensable in the field of robotics.

- Precision: Ensures movements are carried out with exactitude.

- Speed Control: Allows for the regulation of movement speed, crucial for tasks requiring delicate handling.

- Efficiency: Optimizes power consumption, leading to more sustainable operation.

- Adaptability: Facilitates the ability to perform a wide range of tasks by adjusting parameters.

How Do Servo Controllers Enhance Robotic Precision and Efficiency?

Achieving High Precision

Servo controllers are instrumental in maintaining the accuracy of robotic movements. Through the feedback loop, these devices make real-time adjustments to ensure that every motion is executed with unparalleled precision, essential for applications requiring meticulous detail.

Enhancing Efficiency

The role of servo controllers in improving energy efficiency is profound. By optimizing motor control, these systems ensure that robots consume only the energy necessary for the task at hand, reducing waste and extending the lifespan of the system.

What Types of Robotic Systems Benefit Most from Servo Controllers?

Servo controllers find their application across a diverse spectrum of robotics, demonstrating their versatility and critical importance.

- Industrial Robots: Essential for tasks that demand high repeatability and precision.

- Autonomous Vehicles: Provide the necessary control for navigational maneuvers.

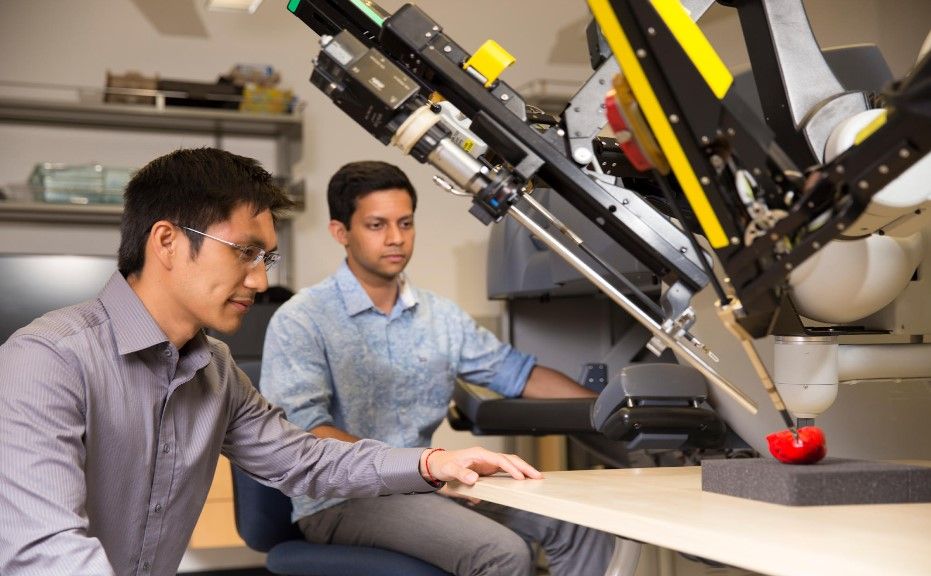

- Medical Robots: Enable the precise movements required in surgeries and patient care.

How Are Servo Controllers Integrated into Robotic Systems?

The Design and Planning Phase

Careful consideration must be given to integrating servo controllers during the robot's design phase, ensuring that the system meets the specific needs of its intended application.

- Feedback Systems: Essential for accurate performance monitoring and adjustments.

- Software Configuration: Tailoring the control software to the specific requirements of the task.

Implementation and Calibration

The implementation and calibration of servo controllers are critical steps in realizing a robotic system's full potential, requiring meticulous attention to detail to ensure optimal performance.

Challenges and Solutions in Servo Control for Robotics

Dealing with Environmental Variability

Environmental factors can significantly affect servo control. Strategies such as adaptive control algorithms and robust design are employed to mitigate these effects, ensuring reliable operation under varying conditions.

Ensuring Reliability and Durability

Maintaining the reliability and durability of servo controllers is paramount for the long-term success of robotic systems. Regular maintenance, along with the selection of high-quality components, plays a crucial role in achieving this goal.

Future Trends in Servo Control Technology for Robotics

The horizon of servo control technology is marked by exciting advancements. Integration with artificial intelligence, miniaturization, and improvements in energy efficiency are set to further revolutionize the capabilities of robotic systems.

How to Choose the Right Servo Controller for Your Robotic Project

Selecting the appropriate servo controller is a critical decision that can greatly impact the success of a robotic project. Factors to consider include torque requirements, speed, control precision, and compatibility with existing systems.

Case Studies: Success Stories of Servo Controllers in Robotics

The transformative impact of servo controllers on robotic systems is best illustrated through real-world applications. These success stories underscore the versatility and efficiency that servo controllers bring to the table, showcasing their ability to solve complex challenges across various industries.

- Industrial Automation: A leading manufacturing company integrated advanced servo controllers into their assembly lines, resulting in a 30% increase in production speed and a significant reduction in errors, demonstrating the controllers' ability to enhance precision and efficiency.

- Medical Robotics: A groundbreaking project in surgical robotics employed servo controllers to achieve unparalleled accuracy in robotic-assisted surgeries. This innovation has enhanced patient safety and outcomes, highlighting the critical role of servo controllers in medical applications.

- Autonomous Vehicles: In the realm of autonomous transportation, servo controllers have been pivotal in enabling precise navigation and control, contributing to safer and more reliable autonomous vehicle systems.

Common Misconceptions About Servo Controllers in Robotics

Despite their widespread use and importance, there are several misconceptions about servo controllers in the field of robotics. Clarifying these misunderstandings is crucial for a comprehensive understanding of their capabilities and limitations.

- Complexity and Cost: Many believe that integrating servo controllers into robotic systems is prohibitively complex and expensive. However, advancements in technology have made servo controllers more accessible and cost-effective than ever before.

- Application Limitations: Another common misconception is that servo controllers are only suitable for high-end or specific robotic applications. In reality, servo controllers are versatile and can enhance a wide range of robotic systems across various industries.

DIY Guide: Building Your First Robot with a Servo Controller

What You Need to Get Started

Embarking on a DIY robot project with a servo controller is an exciting way to explore the capabilities of these devices. Here's what you'll need:

- Servo Motors: The actuators that will drive your robot's movements.

- Microcontroller: Acts as the brain of your robot, sending commands to the servo controllers.

- Power Supply: Ensures your robot has the energy to operate.

- Various Sensors: To enable your robot to interact with its environment.

Step-by-Step Assembly Instructions

Building a basic robot with a servo controller involves several key steps, from assembling the physical components to programming the microcontroller.

- Assemble the Chassis: Start by constructing the body of your robot, ensuring it can support the motors and electronics.

- Install Servo Motors: Attach the servo motors to the chassis, connecting them to the microcontroller.

- Program the Microcontroller: Write the code that will control the servo motors, specifying the movements and behaviors of your robot.

- Test and Troubleshoot: Once assembled, test your robot, making adjustments and troubleshooting any issues that arise.

Safety tips and meticulous testing are paramount to successfully building and operating your first robot with a servo controller.

Conclusion

The pivotal role of servo controllers in enhancing robotic systems cannot be overstated. As the backbone of precision, efficiency, and adaptability in robotics, these devices facilitate advancements across a myriad of applications, from industrial automation to medical robotics. The future of servo controllers promises even greater innovations, driven by emerging technologies and a continuous pursuit of excellence. As we explore and innovate within this dynamic field, the potential for further advancements in robotic systems is boundless. Encouraging further exploration and innovation in servo control technology is not just a call to action for engineers and developers; it's an invitation to dreamers and creators everywhere to imagine and build the future of robotics.