The speed of evolution within artificial intelligence and automation is exciting, yet for companies seeking rapid improvements in productivity, the ROI model is just not adding up. From the time and cost associated with automation to the constraints of very simplistic areas of application, full automation is not always an option. Look closely at any warehouse environment, however, and there are very significant opportunities to augment the performance of the existing human workforce. While processes have been optimised in recent years there are still many aspects of worker activity that are less than optimal. From the physical challenges associated with juggling scanning devices while lifting items, especially at height, to the time wasted walking back to static work stations to input information and receive the next task, there are very significant opportunities to enhance the worker experience, and hence performance.

"The latest generation of ergonomically designed wearables, such as gloves with detachable barcode scanners, can be rapidly introduced to augment day to day worker experience and transform productivity,"

explains Andreas Koenig, CEO,

.

Understanding Automation Reality

Warehouse efficiency has never been more important; yet with the continued labour shortages, it has never been more challenging. With the need to improve both productivity and accuracy businesses are understandably intrigued by the promise of automation. However, while the concept of lights out operations that can run 24/7, 365 days a year is compelling, the reality is somewhat different. Full automation is not achievable today for a variety of reasons. Firstly, it is incredibly complex. There is no simple switch for an efficient, completely automated environment. It takes time and money to train machines to perform required tasks – and few organisations have the skills to create the deep learning structure required. Given the speed of innovation within many product cycles, time becomes a factor. If an item is only in production for a few weeks, even one season, there is not enough time to either train the technology to automate the process or, critically, achieve a return on investment. It is also important to recognise that while progress within this field is impressive, automation technology can today only manage relatively simple processes. As even the technology vendors will confirm, robots cannot handle processes with multiple intricate steps and machines cannot comprehend events that occur outside their sphere of reference.

Value Natural Intelligence

Robots continuing to perform their simple, preprogrammed processes while the warehouse burned down around them may be an extreme, recent example but there are many events where a human’s natural intelligence is still essential to ensure problems are immediately resolved. Drop an item and a human will pick it up, check for damage and move on. Unless it has been trained to undertake every one of those steps, a robot will be stymied. Of course, automation has an important role to play, especially in handling simple, repeatable processes; but it is no panacea. To meet the challenges of transforming productivity, the existing workforce remains essential. With the added pressure of recruitment and retention facing the industry, organisations must therefore look at opportunities to augment and enhance the worker experience to improve efficiency, safety and morale.

Human Centric Design

One of the biggest challenges for improving productivity is that humans get tired. From stamina to muscle power, errors typically increase as workers run out of steam. For this reason, the science of ergonomic design has become ever more important to maximise both performance and worker comfort. One key opportunity is to minimise extraneous movement and ensure the majority of physical movement is directly linked to productive activity. For example, replacing the traditional point and shoot barcode scanner with a glove with in-built scan functionality offers a number of benefits. Obviously, the worker has both hands free at all times to pick up items and safely negotiate warehouse locations, often at height. The wearable devices are always to hand; the worker simply presses a button in the glove to scan an item, making the entire process much easier. Furthermore, there is no need to put down and pick up the device; while scanners are relatively lightweight, even removing this level of additional weight from a worker can have a tangible impact on fatigue.

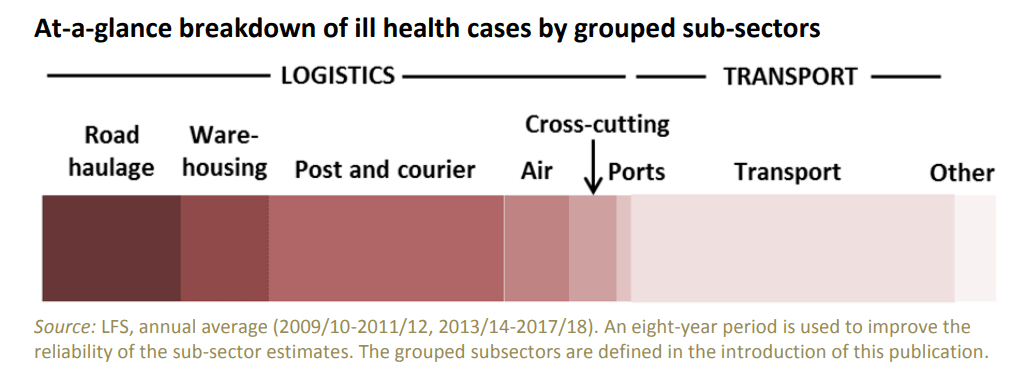

The hands-free nature of wearable devices can also improve worker safety – a key issue since the majority

of health and safety incidents

reported in the UK in 2017/18 within the transportation and storage industry related to musculoskeletal disorders. In addition to avoiding one handed pick up of items, a wearable scanner eradicates the risk of scanners being dropped on other workers. In addition, wearables can include sensors and emit a signal to alert other workers to an individual’s presence, addressing the risks created by forklifts and other moving infrastructure.

Knowledge Driven Performance

In addition, such wearable devices improve picking accuracy by using adjustable feedback options, such as acoustic signals, vibration and LEDs on the back of the hand to provide immediate confirmation of correct product selection. By helping the worker to rapidly distinguish between ostensibly identical products, for example, helps to minimise both delays and errors. This not only drives up productivity but also avoids worker frustration. These wearables can also be connected to other devices such as tablets, smartwatches or wearable terminals to provide individuals with additional information. Rather than time consuming – and tiring – treks back to a static information display, workers can immediately be provided with the next pick location, for example. Essentially, wearable devices enable individuals to avoid extraneous, tiring activity: every step, every arm movement is directly related to undertaking the task at hand. Of course this efficient, augmented workforce will increasingly work with machines. Automation technology and artificial intelligence will continue to evolve, releasing human workers from the tedium of many simple processes. The provision of real-time information via wearables will be an essential component of this intelligent, augmented human workforce, supporting a team of informed individuals taking on increasingly complex, changing and time-sensitive tasks in tandem with automation.

Wearables Ecosystem

The implication for businesses of this augmented human workforce is significant. Scanning time reduced by up to four seconds per scan. Minimising unnecessary and tiring repetitive actions and improving accuracy significantly increases the volume of work undertaken by each worker. Augmenting the workforce will rapidly transform productivity and efficiency. This is just the start. As the evolution of wearable devices continues, workers will increasingly be able to leverage an ecosystem of wearables that will enhance not only human collaboration but also human to machine interaction. From gloves to glasses and cameras, the augmented human workforce will be not only more productivity but safer and, hopefully, happier.